week 8

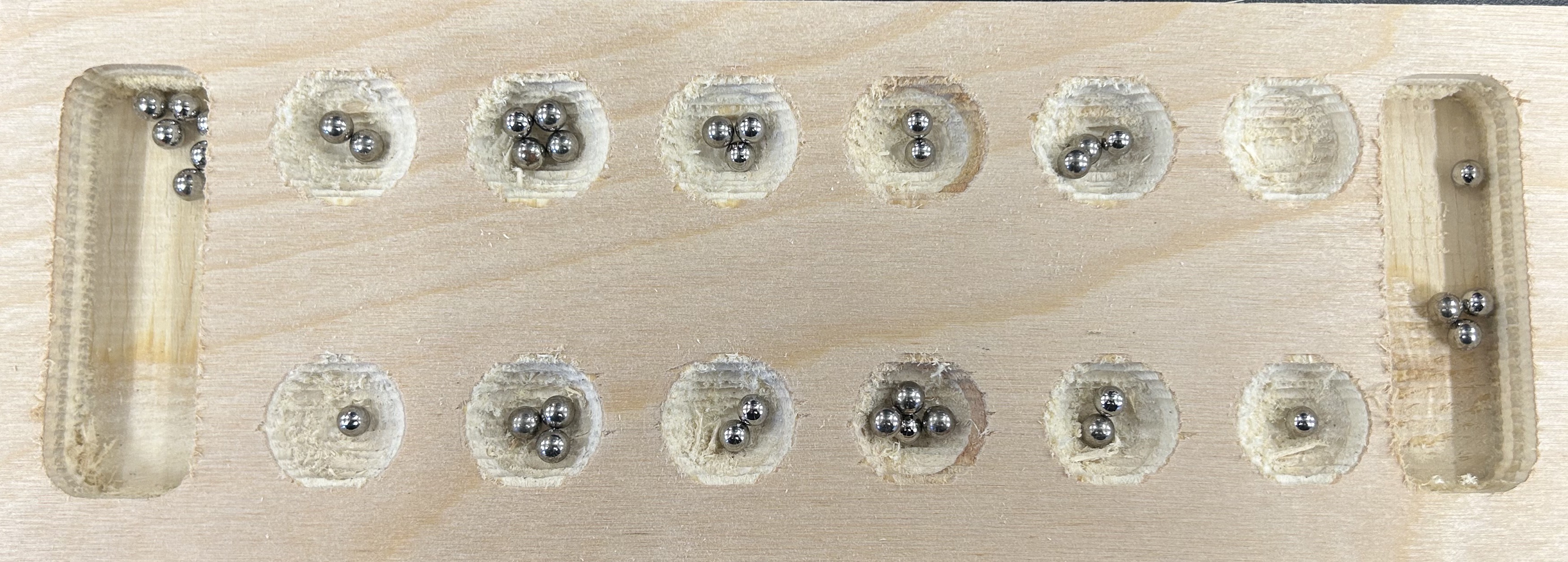

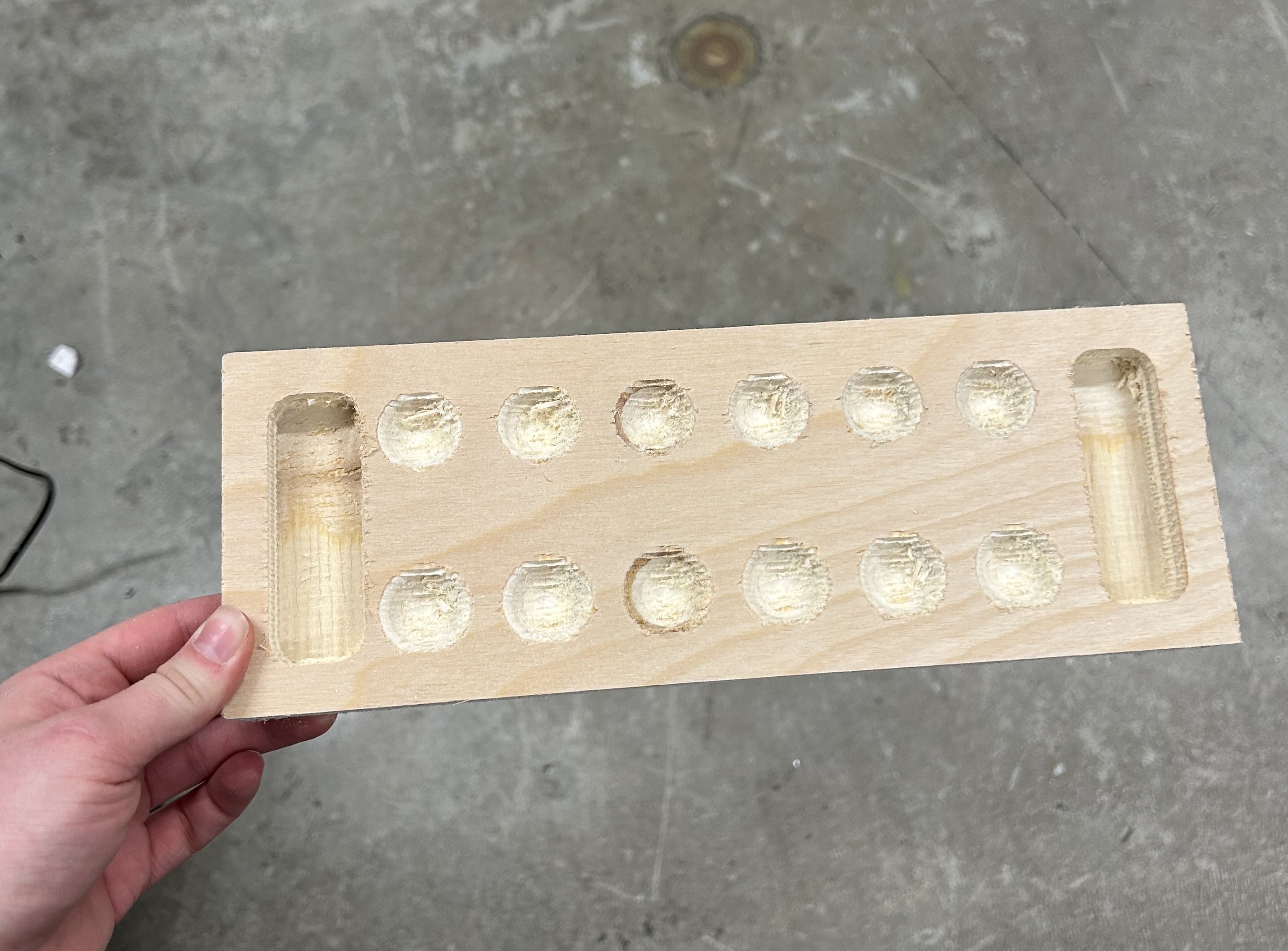

This week, I set about making a mancala board. The board is usually wooden, and the beads are usually marbles. Using CNC milling I planned to make the board itself, and I used small metallic balls for the marbles, since my board is a bit smaller than normal.

Mancala board

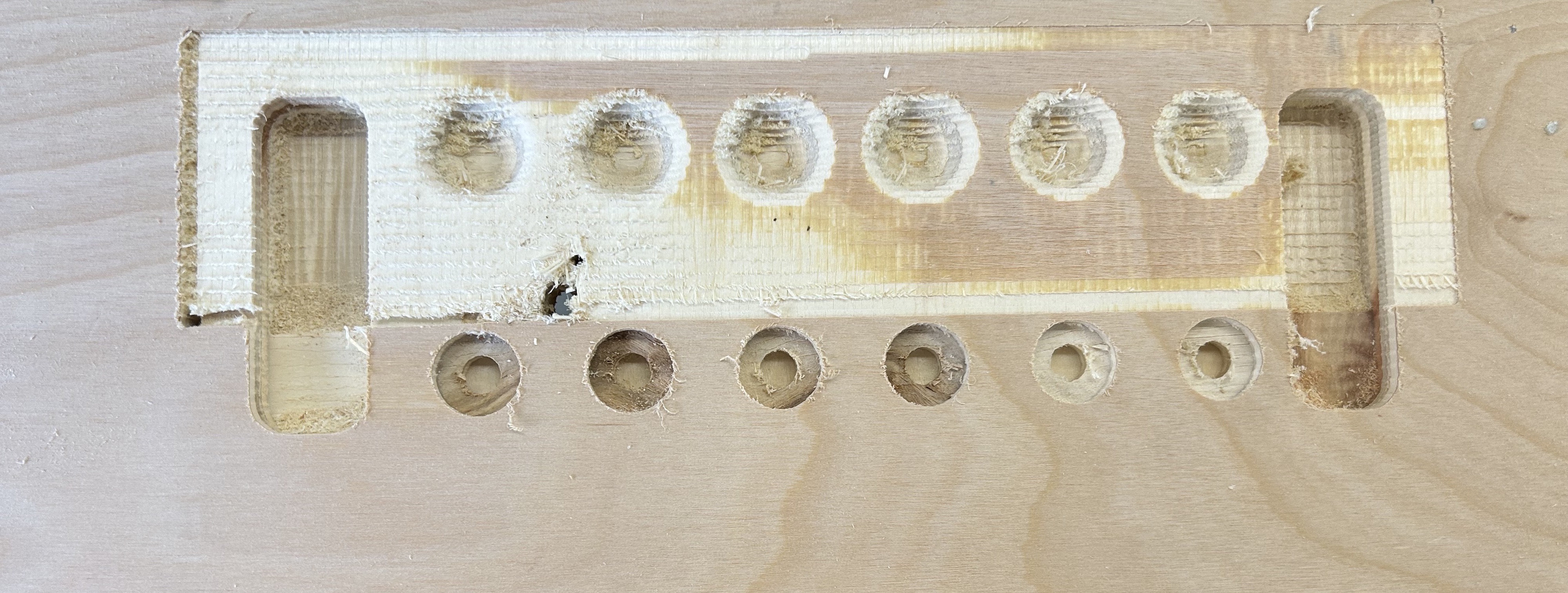

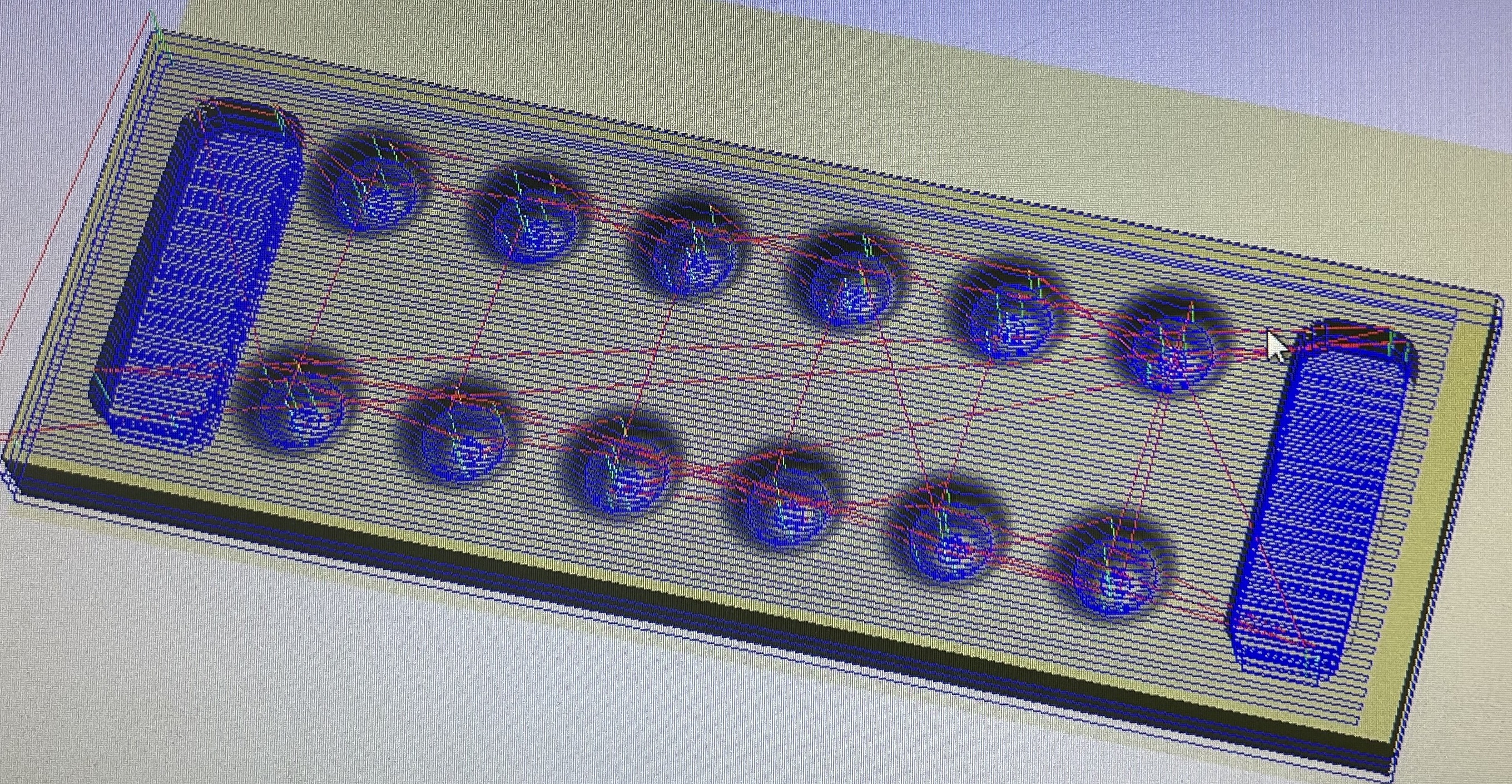

With some help, I was able to put my STL file into Aspire and find a toolpath which would cut out my board. Unfortunatley, I did not mount my board well enough and halfway through the finishing pass, the board came off of the platform. It was destroyed, RIP :(

One of the main issues was that the right boundary of the board was being cut with each pass, meaning that the endpiece would remove wood from one point on the boundary in a drilling motion and pull straight upwards. On my next attempt, Bobby helped me remove that feature of the toolpath so that the boundary would be cut out in a more cautious way.

The toolpath^

Success! What a rewarding expereince.

Casting and molding

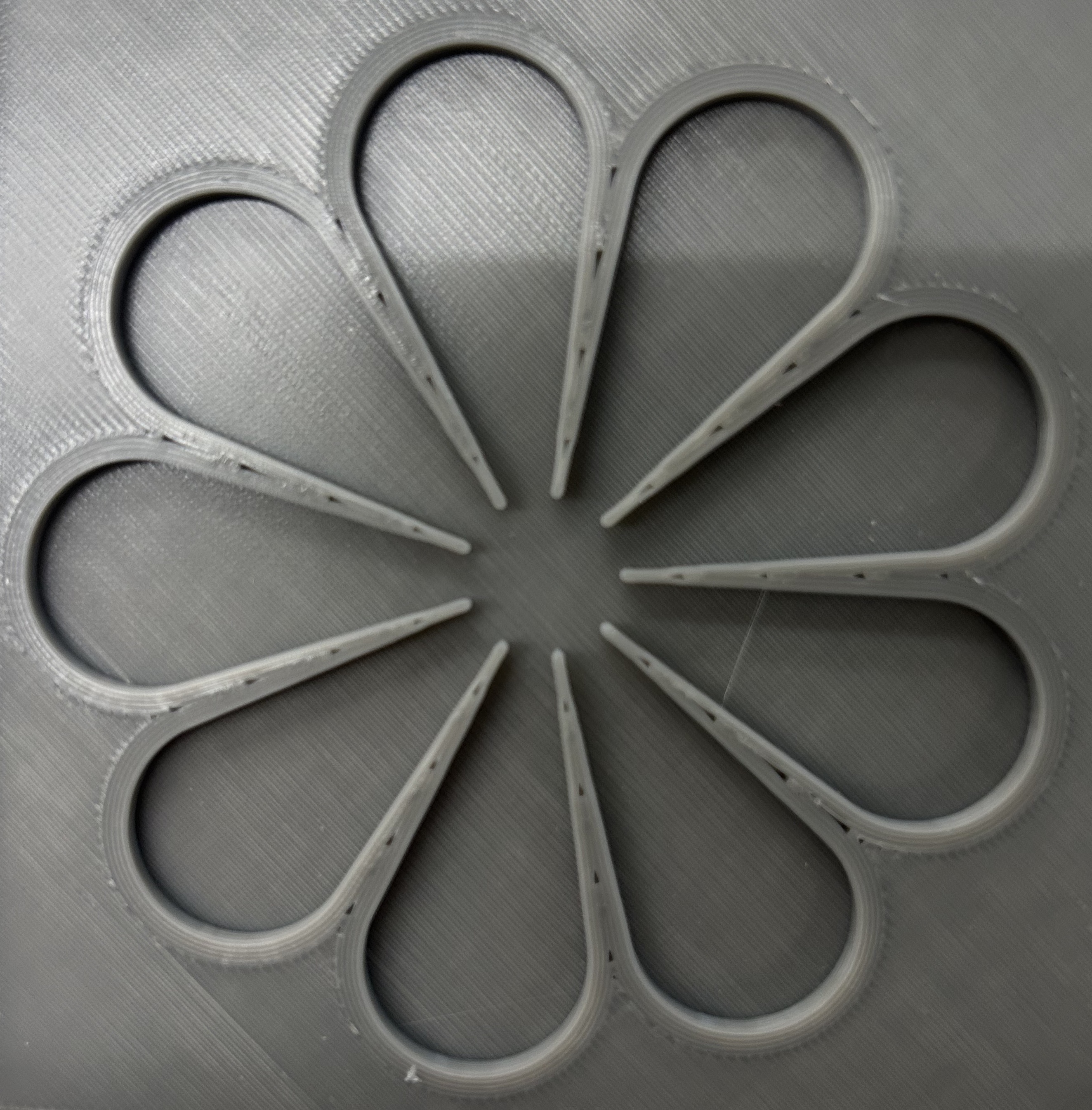

I spent some time thinking about what I wanted to cast/mold. I decided that I wanted something kind of funky that would be tricky to reproduce in another way and landed on a colorful, flexible, flower coaster for my desk. I decided to 3D print the negative of my design to use as a mold, and then filled that with silicone. I tried to mix in food dye, which did not blend well at all, but left a cool speckling effect. I decided to add in some purple acryllic paint, just for fun. I poured the mixture in the mold. Time to wait!

The negative^

Filled with silicone!^

The result looks a bit dirty, which is likely an artifact of the food dye which never fully blended. However, from afar, the final product has a nice purple hue! I like the texture and the overall look of my flower coaster.

Perfect to save my desk from coffee-cup condensation!